Ever felt stuck trying to find the right company to bring your plastic product idea to life? Wondering if anyone gets what you need, without charging a fortune or forcing you into crazy high minimum orders? You’re not alone. That’s why we’re here to talk about Hongbangyi Plastic, the go-to name

when it comes to Custom Plastic Injection Molding. We’ve been at it for decades. We’ve seen what works, what doesn’t, and what makes clients come back again and again. Let’s walk through what makes us different—and why that matters for you. The advantages of our custom plastic injection molding include consistent quality, cost savings, and high precision molds, all contributing to a superior production process.

Introduction to Hongbangyi Plastic – your trusted injection

molding company

Hongbangyi Plastic is a leading custom plastic injection molding company that specializes inproviding high-quality plastic parts to various industries. With extensive expertise in the plastic injection molding process, we offer a wide range of services, including custom plastic parts, molded parts, and assembly

services.

Our team of experienced professionals is dedicated to ensuring consistent quality and meeting the specific needs of our customers. We utilize state-of-the-art equipment, including CNC machines, to

produce high-quality parts with tight tolerances. Our commitment to quality control and assurance ensures that our customers receive the best possible products.

Why Custom Plastic Injection Molding Isn’t

One-Size-Fits-All

Let’s be honest—not every plastic part is made for the same reason. Sometimes, you only need a one-off prototype to test your idea. Other times, it’s a small batch for early user feedback. And of course, there are projects where steady, repeatable production is what you’re after. That’s where a reliable supplier becomes everything. At Hongbangyi Plastic, we also handle end-use

production parts, so what you get is strong, clean, and built to

last. This is why custom plastic injection molding stands out. It’s not a factory template or a one-size-fits-all deal. It’s flexible, made to fit your project, your way.

Here’s what makes it different:

- Low Minimum Order Quantities (MOQ)

You don’t need to order thousands of parts just to get your foot in the door. We’re set up to support low-volume orders, so you can test ideas or enter markets without blowing your budget. - Fast Prototyping

Got a CAD file or even just a sketch? We’ll turn that into a working model using CNC machining or 3D printing. This means you can test, tweak, and move forward faster, with fewer surprises down the line. - OEM & ODM Support

If you’ve already got a full design ready, great—we’ll build to spec. If not, no worries. We can help design your part from scratch, offer suggestions, and guide you through material choices, tolerances, and finishes. - High-Quality End-Use Parts

Some clients come for prototypes, others for full production. Either way, the focus is always on quality. We build moulds that can handle the pressure, plastics that hold their shape, and finishes that look good right out of the tool.

In short, you’re not getting cookie-cutter plastic parts. You’re getting parts tailored to fit your idea, your budget, and your timeline.

Whether it’s 10 units, 1000 units, or a first step into something much bigger, we’re here to help make it happen. Because that’s what custom plastic injection mold services are really about: making your project work on your terms.

What Makes Hongbangyi the First Option for Custom

Plastic Parts?

Think about it like this:

You’re not just buying plastic. You’re buying peace of mind. Our Plastic moldings services are essential to enhancing your business’s productivity and efficiency.

We help you skip the stress with:

- Precision injection molding that guarantees consistency

- Plastic moldings built for real-world use

- Injection mold design that holds up under pressure

- Full plastic injection process support from start to finish

Whether it’s automotive injection molding, medical injection molding, or consumer products, our shop’s seen it all. And made it all.

From Sketch to Shipment: The Hongbangyi Process for the

Injection Molding Project

So, how does it work when you partner with us?

Here’s the breakdown:

- You send us an idea – Could be a sketch, a concept, or a 3D file

- We check feasibility – Material options, part design, budget, timing

- You get an online quote, with zero pressure

- We build the mold – Using plastic injection tooling and CNC machining

- Test the samples – Small runs to ensure fit and function

- Full run begins – Low or high volume, we handle both

- We complete the process, ensuring the timely delivery of high-quality products

- We support shipping – So your parts land exactly where you need them

We’re not just a plastic injection molding company—we’re your team.

Plastic Materials? We’ve Got Plenty

Not sure which plastic fits your project?

We help you pick from a full range of plastic injection

materials, like:

- ABS injection molding (great for strength and rigidity)

- Thermoplastic molding for flexibility

- Clear or tinted options

- FDA-compliant choices for medical injection molding

Different needs. Different plastics. All covered.

Proper packaging is crucial for the safe transport of tools, and customers are accountable for shipping and packaging costs after the completion of a run.

Industries We Work With – And Why That’s Good News for

You

Because we’ve worked across multiple fields, we bring broad experience to the table:

- Automotive – Tight tolerances? No problem.

- Medical – Clean, safe, reliable medical devices.

- Consumer goods – Toys, cases, housings—ready for shelves.

- Industrial parts – Built to perform.

This means you get smarter suggestions, better materials, and faster fixes.

When Low Volume Injection Molding Makes the Most

Sense

Big production lines aren’t always the answer. Sometimes you just need a short run. We handle that with:

- Cost-effective low volume injection molding

- Quick turnaround on injection molded prototypes and production parts

- Flexible planning so you’re not locked in

Perfect for testing markets or getting a new product off the ground.

Real Story: How One Client Saved Time and

Money

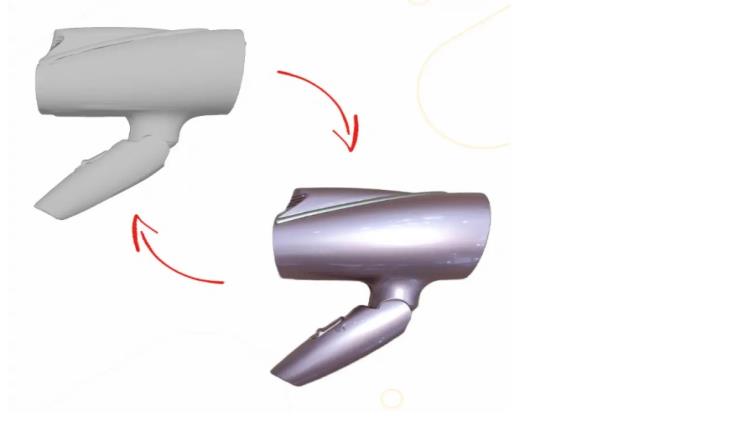

A startup came to us with a home appliance component.

They needed a clean look, high durability, and an urgent timeline.

Our team:

- Helped redesign the part using smart plastic molding techniques to create custom molded parts

- Ran a prototype molding batch with fast 3D printing

- Kicked off injection molding production in days

They launched in under 3 months, with rave reviews. That’s the kind of support we’re proud of.

We’re Built for Flexibility

Every customer gets a custom path.

- You want full design help? Done. Our design team, with extensive experience and advanced design software, ensures your specifications are met.

- Need someone to just build on your file? Easy.

- Prefer email-only communication? Sure thing.

- Want updates by phone or video? We’ve got time.

Working with plastic injection experts should feel like working with people, not robots.

Behind Every Great Part Is Great Tooling

Let’s not forget about the heart of it all: the mold.

That’s why our injection mold fabrication team takes it seriously:

- Solid steel or aluminium base options

- Polish, texture, engraving, cavity design—it’s all on the table

- Tight tolerances for tight parts

Better molds = better parts = happier clients.

Our In-House Tech: More Than Just

Machines

Yes, we’ve got machines, and more importantly, we know how to use each machine to its full potential. From CNC machining to plastic manufacturing solutions, every step is managed by pros. We also specialize in EDM machining, ensuring precision in every project.

We work in:

- CAD (we can build or fix your 3D files)

- CAM

- CNC

- SLA & FDM 3D printing

- Sheet metal for multi-material builds

All under one roof.

Quality Control and Assurance

At Hongbangyi Plastic, we take quality control and assurance of the manufacturing process seriously. We have a comprehensive quality control process in place to ensure that our products meet the highest standards.

Our team of quality control specialists inspects every part that leaves our facility to ensure that it meets our strict quality standards. We also use advanced technology, such as automated inline CMM, to ensure dimensional accuracy and generate detailed process capability studies and FAI reports.

Our quality control process includes regular inspections, testing, and evaluation to ensure that our products meet the required specifications. We are committed to providing our customers with high-quality products that meet their specific needs and requirements.

Cost-Effective, Without Cutting Corners

We know price matters.

But cheap parts? That’s a cost you’ll feel later. We offer:

- Low-cost, competitive pricing

- Scalable volumes

- Transparent quotes

No surprises. Just good parts made right.

How to Get Started

You don’t need to jump through hoops. Just reach out with:

- A sketch, sample, or idea

- What you need (part size, quantity, material)

- Your timeline

We’ll handle the rest. Partner with us for your next injection molding project to ensure success.

Quick chats. Clear timelines. Honest answers.

Let’s Build Something Real

If you’ve been burned by other injection molding services or you’re tired of guessing who to trust, let’s make it easy.

We’re Hongbangyi Plastic, your trusted mold makers, your professional plastic injection molding partner with several production line, CNC machine, and serving multiple industries, with good product inventory management. Believe we can support your custom parts sampling and production.

We’re your people for:

- Custom molding solutions

- Custom plastic products

- Everything from idea to production to delivery

- Being your reliable injection molding supplier

With real talk. Real pricing. Real results.

Because when it comes to custom plastic injection molding, you shouldn’t have to settle.

We’re ready when you are.