When it comes to industrial pumps, progressive cavity pumps are becoming increasingly popular. Arguably, their principal value is that they’re reliable and efficient but are also easy to install and maintain. Still, many find the basics of progressive cavity pumps, their many applications, and their advantages a vague topic that needs elaboration. Fortunately, we’ll help you learn about progressive cavity pumps. Finally, we’ll outline some factors to consider when choosing the most suitable one for your business.

What is a Progressive Cavity Pump?

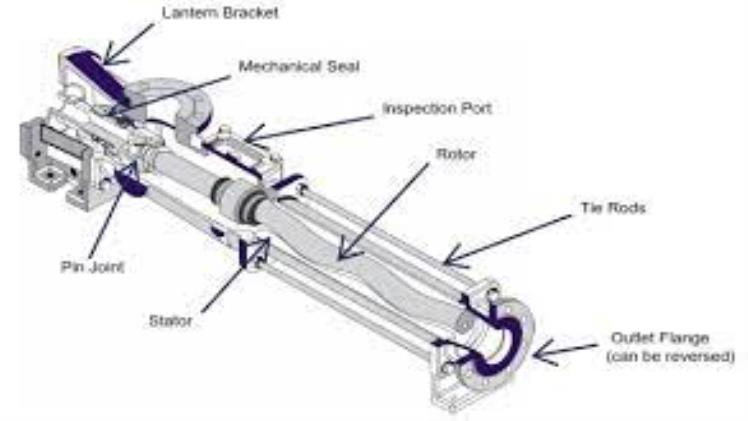

Progressive cavity pumps, often called a PC pumps or helical rotor pumps, are positive displacement pump for moving heavy or abrasive liquids. It contains a single winding rotor positioned eccentrically inside a double-helical stator. The mechanism creates a series of chambers that go from the intake to the pump’s output side.

As the rotor spins, the space between the rotor and stator becomes an airtight seal, pushing the fluid along the pump. It displaces the fluid continuously and smoothly, making it an ideal choice when gentle pumping action is needed.

How Does a Progressive Cavity Pump Work?

A progressive cavity pump operates on a unique principle of positive displacement. As mentioned, it consists of a single rotating winding rotor and a double-helical stator. The rotor and stator create a series of cavities that move fluid from the suction side to the discharge side of the pump.

When powered on, the space between the rotor and stator is initially void. As the rotor commences its rotation, the compartments progress from the inlet to the outlet, thereby suctioning in liquid.

As the spaces transition, the rotor motion produces a barrier between the rotor and stator, holding the liquid confined. Consequently, the mechanism establishes a positive displacement action, pushing the fluid from the suction to the release side.

The rotor’s spinning persists, keeping the liquid in place and progressing via the pump. The progressive cavity pump’s original configuration enables an even, persistent stream of liquid, rendering it ideal for procedures requiring a subtle pumping action.

The stream velocity is contingent on the rotor’s speed and the size of the compartments. By adjusting these factors, manufacturers can tailor the pump to match special flow specifications.

Advantages of Progressive Cavity Pumps

Progressive cavity pumps have applications in various industries owing to several unique advantages. The following are some of the critical benefits of progressive cavity pumps:

Versatility

These pumps can manage various fluid viscosities, from runny liquids to exceptionally viscous compounds. Usually, they can successfully pump fluids of up to 1,000,000 centipoises. This feature brings use cases in oil, gas and wastewater treatment, food processing, and chemical manufacturing.

Self-Priming

One of the primary advantages of progressive cavity pumps is their capacity to start pumping without manual priming or auxiliary equipment. This attribute saves time and effort and lessens downtime and maintenance costs.

Delicate Pumping Action

These pumps provide a smooth and consistent fluid flow, making them apt for delicate pumping situations. Their positive displacement mechanism guarantees that the fluid is moved with no jolts or waves, which helps to reduce the chances of harm to the fluid or the pumping system.

Enhanced Efficiency

Progressive cavity pumps have great volumetric effectiveness, enabling them to quickly shift a large amount of fluid. This is especially advantageous in situations that require rapid flow rates.

Simple Maintenance

These pumps are easy to set up and maintain since they have only a few moving parts. This feature reduces the probability of malfunctions and the requirement for constant repairs. Furthermore, their compact shape enables effortless access and maintenance in restricted areas.

Common Applications

Progressive cavity pumps are versatile and efficient, making them suitable for various applications across various industries. Here are some typical applications where progressive cavity pumps are widely used:

Oil and Gas Industry

Progressive cavity pumps are common in the oil and gas industry for handling viscous fluids such as crude oil, bitumen, and drilling mud. They can efficiently handle high-viscosity fluids and solids-laden slurries, making them ideal for oil well stimulation, well cementing, and offshore drilling operations.

Wastewater Treatment

Progressive cavity pumps are popular in wastewater treatment plants for pumping sludge, sewage, and other waste fluids. They can handle the high solids content in wastewater and provide a reliable pumping solution for processes such as sludge dewatering, transfer, and effluent pumping.

Food Processing

Progressive cavity pumps are widely popular in the food processing industry. Typically, they help handle viscous food products like sauces, purees, pastes, and dough. Their gentle pumping action ensures minimal damage to the food products. Consequently, it makes them suitable for filling and transferring food ingredients, packaging, and processing dairy.

Chemical Manufacturing

Progressive cavity pumps are standard for pumping various chemicals, solvents, and corrosive fluids. They can handle multiple chemical viscosities and provide a reliable metering, dosing, and chemical transfer application solution.

Mining and Minerals

In mining operations, progressive cavity pumps pump abrasive and viscous materials such as slurry, tailings, and mineral concentrates. They can handle high solids content and provide efficient pumping solutions for mine dewatering, slurry transfer, and tailings management applications.

How Progressive Cavity Pumps Handle Viscous Fluids

Viscous fluids can present a challenge when it comes to pumping. Their thick consistency and resistance to flow can make it difficult for traditional pumps to move them effectively. However, PC pumps can efficiently handle viscous fluids.

The unique design of progressive cavity pumps allows them to handle viscous fluids using a positive displacement action efficiently. As the rotor rotates within the stator, the cavities formed between the two create a seal, trapping the liquid inside. This seal prevents the fluid from slipping back and ensures a continuous and consistent flow.

Thanks to their constant flow rate, the progressive cavity pump is a great option when it is crucial for accurate and consistent liquid delivery. Moreover, they can handle materials with solid or abrasive elements without risking blocking or damaging the pump.

Final Thoughts

In conclusion, progressive cavity pumps represents a vital part in fluid handling technology, bringing about dependability, effectiveness, and adaptability. Being a crucial part of fluid transfer systems used by various industries such as biomedical, engineering and aerospace, its quickly becoming popular for its application in these industries.

For those seeking top-notch dispensing valves, TechnoDigm™ is the company to go for. Elevate your fluid handling processes with the high-quality progressive cavity pump offered on the website in the ever-evolving landscape of industrial pumping solutions.